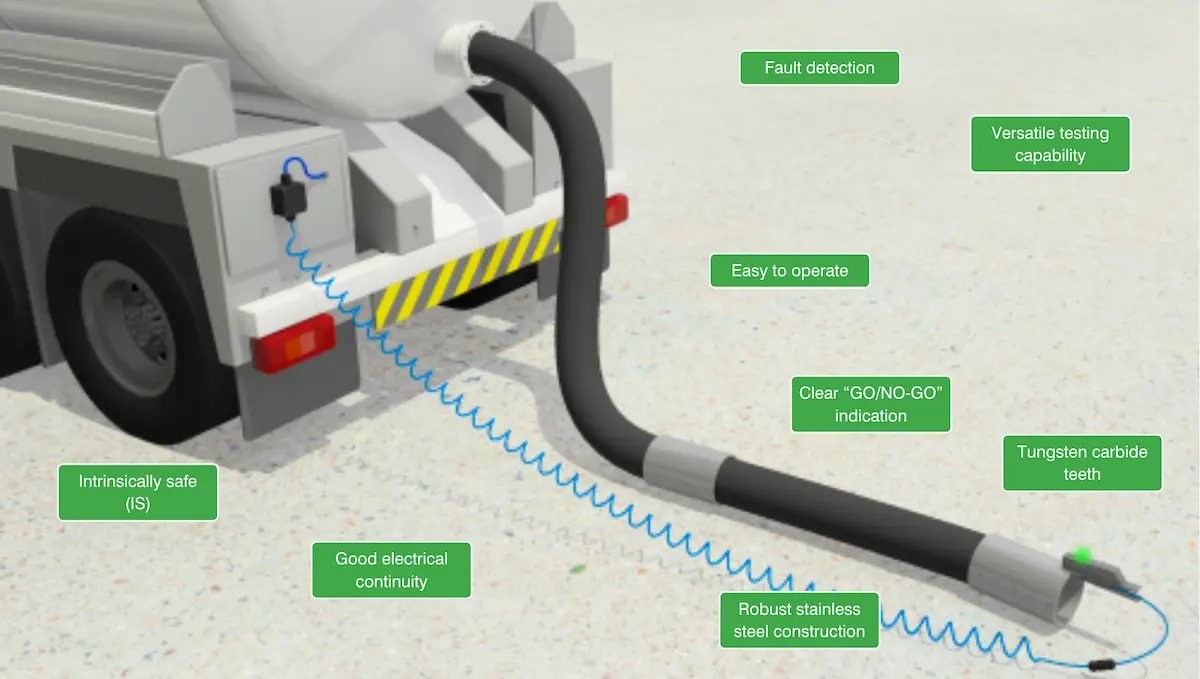

A one-time test provides operators with a simple “GO/NO-GO” indication via a highly visible flashing green LED mounted on the lid of the OhmGuard®.

Proves the hoses have good electrical continuity with the grounded truck.

Requires minimal training for drivers and operators.

Provides operators with a visual indication of a true connection via a flashing green LED, enabling early detection of faults and component errors without waiting for scheduled periodic testing.

Compliant with HAZLOC requirements for safety.

Robust stainless steel construction offering greater durability and longevity than other multimeters in the field.

Strong and durable tungsten carbide teeth effectively penetrate slurries or deposits caked onto the hose end fitting.

Learn more about Industry Standards and Guidelines relating to static electricity in explosive hazardous locations:

- Gain insights into the specification of HAZLOC certified equipment.

- Understand standards referenced in the industry.

- Learn about the selection of HAZLOC equipment.

- Evaluate competency requirements for individuals.

- Navigate HAZLOC equipment documentations.

cCSAus Certificates - United States

IECEx Certificates - International

ATEX Certificates - Europe

UKCA Certificates - United Kingdom

CCC Certificates - China

KCs Certificates - South Korea

The OhmGuard® electrical continuity tester

The OhmGuard® electrical continuity tester is designed to test hoses used on vacuum trucks, tanker trucks, and plant equipment prior to the transfer of flammable or combustible products.

Hoses play an important role in HAZLOC operations, and owing to their direct interaction with moving liquids and powders, they can be at risk of becoming electrostatically charged. At no point in its structure should the metal components of a hose be permitted to accumulate static electricity.

Examples of metal components that have the potential to accumulate static charge are couplings and metal wire helixes.

OhmGuard® applications

- Testing vacuum truck hoses prior to spill cleanup or material recovery operations.

- Testing bulk tanker trucks hoses prior to the delivery of flammable products (e.g. solvents) to storage tank farms.

- Testing bulk tanker trucks hoses prior to the delivery of flammable products (e.g. solvents) to storage tank farms.

- Spot testing of bonding assemblies and conductors in the field.

Easy to operate

Easy to operate with a one time test with clear visual GO/NO-GO LED indication.

Fault detection

Periodic resistance testing of hoses with meters by a responsible person (experienced electrician) helps identify potentially faulty hoses so that they can be removed from service.

Another option is to supply drivers with an easy-to-use hose continuity tester that provides an LED indicator to indicate a PASS or FAIL test of the hose. It should be emphasized that drivers must be suitably trained as being competent to use such testers.

High intensity flashing green LED

Request a live product demo

Newson Gale has an extensive product range that can be tailored to your processes and the range of HAZLOC classifications at your location.

The most effective way to identify what is applicable for your operations is by speaking with our team. They will provide in-depth information on the products, features, and how the range of options can be tailored to your needs.