Case Studies

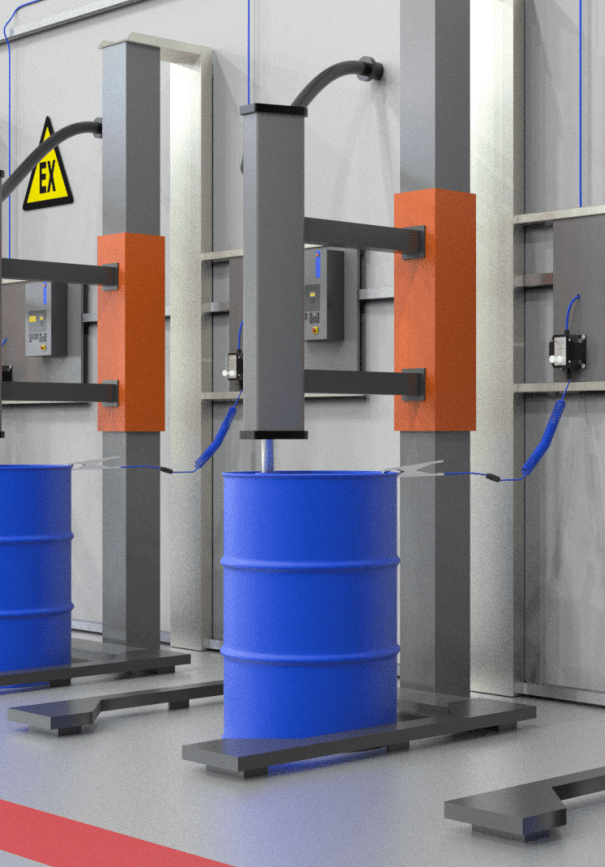

Storing and Handling Flammable Liquids Safely

Case Studies

Risk of Electrostatic Ignition during Storage Tank Cleaning Operations

Case Studies

Risk of Electrostatic Ignition during FIBC Discharging Operations

Case Studies

Risk of Electrostatic Ignition during Powder Processing Operations

Case Studies

Spark from Isolated Hose Ignites Combustible Powder Atmosphere

Case Studies

Drawing Toluene

Case Studies

Dust Cloud Ignition Prevention, From Static Electricity

Case Studies

Electrostatic Ignition of Toluene Vapors